Why Plate Heat Exchanger Is More Efficient?

Plate heat exchangers (PHEs) are often the most efficient choice for heat transfer in modern industrial applications. By stacking many thin, corrugated metal plates, PHEs achieve enormous heat transfer surface per unit volume – often 100–200 m²/m³, compared to only 20–50 m²/m³ for a typical shell-and-tube unit. The corrugations in each plate induce turbulence even at moderate flow rates, yielding heat-transfer coefficients on the order of 3,000–7,000 W/m²·K for liquid-to-liquid service.

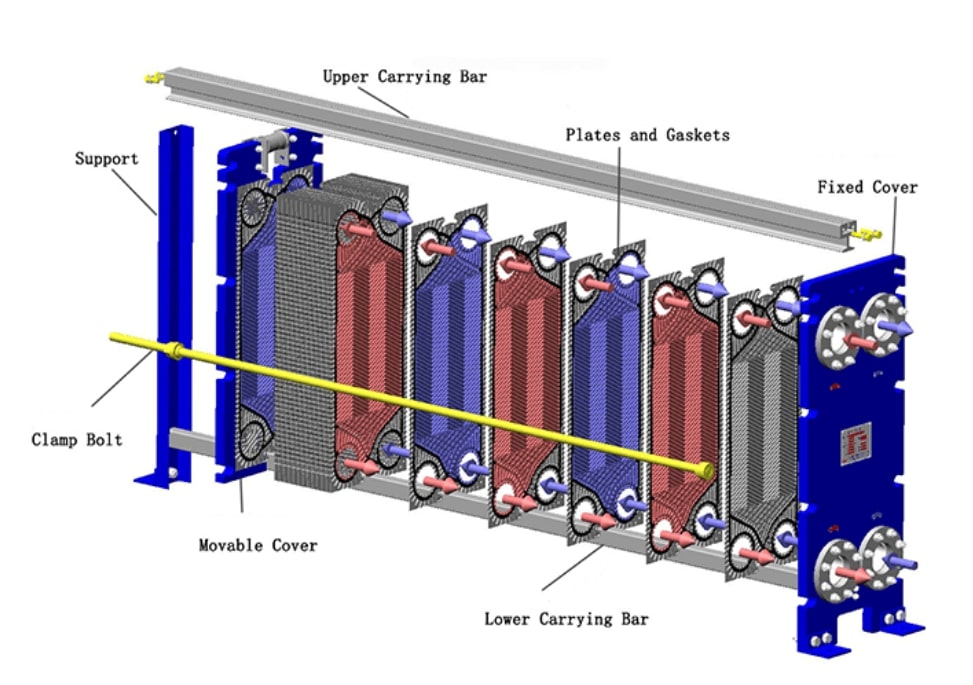

Thin plates are clamped between carrying bars to form alternating hot/cold channels.

Plate-and-frame heat exchangers squeeze fluid between corrugated plates to multiply the contact area. Compared to a bulky shell-and-tube bundle with a single large shell, the plate design fits the same duty into a fraction of the space. Many manufacturers report a 70–90% smaller footprint for PHEs versus equivalent shell-and-tube units, thanks to the much higher area density. This compactness also often translates to lower upfront cost: industry guides note that plate exchangers typically require less material and cost less than comparable tube bundles.

Comparing Plate vs. Shell-and-Tube Exchangers

Heat exchangers come in many forms, but the most common industrial types are shell-and-tube, plate-and-frame, and various finned-tube (or plate-fin) designs.

Feature | Shell-and-Tube Heat Exchanger | |

Heat Transfer Efficiency | High (3,000–7,000 W/m²·K) | Moderate (500–1,500 W/m²·K) |

Footprint | Compact | Bulky |

Maintenance | Easy (accessible plates) | Labor-intensive (tube bundle) |

Pressure Handling | Up to 60 bar (welded types) | Very high (200+ bar possible) |

Initial Cost | Low | High |

Scalability | Modular (add plates) | Requires full redesign |

In summary, Plate heat exchangers are up to five times more efficient than shell-and-tube exchangers, making them ideal for energy recovery, HVAC, food/pharma, chemical, and many other industries where fluids are relatively clean and space or cost is a concern.

A common case study in industrial energy audits shows that switching from shell-and-tube to plate exchangers can cut thermal energy consumption by 15–30% in some processes.

Outstanding Thermal Efficiency

The outstanding thermal efficiency of compact plate heat exchangers stems from their geometry and flow.

Key factors include:

Extreme Surface Area Density:

Stacked plates create far more area for heat exchange than cylindrical tubes. PHE surface-area density can reach 100–200 m² per m³ of volume, versus only 20–50 m²/m³ for shell-and-tube systems. Every 10 °C of temperature difference across a heat exchanger produces more heat transfer when more area is available, so this big area boost directly ups performance.

Thin Plates, Short Conduction Paths:

Plates are typically 0.4–1.0 mm thick. The metals (stainless steel, titanium, nickel alloys) conduct heat quickly, and the thinness means the conduction distance is small. This yields high overall heat-transfer coefficients. In practical terms, plate exchangers often see U-values in the thousands of W/m²·K, compared to a few hundred for an equivalent shell-side fluid or finned coil.

Turbulent Flow Channels:

Each plate has chevron or herringbone corrugations etched or stamped. As fluid flows through a thin, corrugated gap, the pattern forces turbulence even at modest flow rates. This disrupts boundary layers and keeps the convective heat transfer very high. Corrugation patterns can more than double the heat transfer coefficient compared to smooth channels.

Efficient Flow Paths:

Most PHEs use alternating hot/cold channels and often configure the fluids in counterflow (or multi-pass counterflow) arrangements. Counterflow means the hot and cold streams move in opposite directions, allowing the maximum temperature difference along the exchanger and enabling minimal “pinch” (approach) temperatures. In ideal counterflow, the cold outlet can theoretically approach the hot inlet temperature, maximizing driving force. Some designs even achieve a temperature cross (hot outlet cooler than cold outlet) in extreme counterflow configurations – something virtually impossible in single-pass shell-tube units.

An engineering benchmark notes that a multi-tube bundle is ~12× more efficient than one big tube of the same volume; PHEs multiply that effect even further.

Flow Dynamics and Pressure Drop

While pillow plates boost heat transfer, they also raise pressure drop because fluids negotiate tight, tortuous paths. Designers balance efficiency with hydraulic cost:

Optimized Plate Geometry:

Heat-exchanger makers adjust corrugation angle, depth, and plate spacing to tune performance. Narrower channels and steeper corrugations increase turbulence (and heat transfer) but also increase pressure drop. Many modern PHE designs optimize the plate geometry to hit a sweet spot of very high heat transfer with acceptable pumping power.

Multi-Pass and Counterflow:

To maintain high efficiency in limited space, PHEs often use multi-pass flow. The fluids zig-zag through several plates before exiting, effectively simulating long flow paths in a small package. Counterflow or cross-counterflow layouts further enhance temperature gradients.

Pressure Drop Management:

Manufacturers actively control pressure drop. Wide-gap plate designs and large nozzles reduce pressure loss in viscous or particulate flows. Even in compact PHEs, the pressure drop is often comparable to a similar shell-and-tube unit, but the heat transferred is much higher, so the overall energy efficiency (heat per pumping watt) can still favor plates.

The combination of high heat-transfer coefficient and reasonable pressure drop means PHEs often enable smaller, more energy-efficient system designs.

Compactness and Space Savings

One of the most striking advantages of plate heat exchangers is their compactness. Thanks to their high area density, PHEs deliver the same heat duty in far less volume and weight than shell-and-tube units. Typical data points:

Footprint Reduction:

Industry sources cite 70–90% smaller footprint for plate units compared to tubes. This matters in plants where rack space and piping runs are at a premium.

Lower Material Use:

A compact exchanger uses less steel and fewer components. This often reduces cost. Less volume also means smaller tanks of fluid to heat or cool, improving system control.

In industrial heat exchanger design, this size advantage cannot be overstated. In a chemical processing plant or power station, dozens of exchangers might share pipe rack space. Using plates can double or triple the number of exchangers in the same area. Many modern skids and OEM systems now specify plate exchangers primarily for their space-saving qualities.

Specialized Plate Heat Exchanger Designs by SHPHE

The core advantages of plate heat exchangers are further enhanced by the evolution of several specialized designs tailored for challenging industrial conditions.

Gasketed Plate Heat Exchangers (GPHE)

These are the most common form of plate heat exchangers, featuring corrugated plates sealed by elastomeric gaskets. They are ideal for fluids that must be kept separate and for systems requiring frequent disassembly or cleaning.

Applications: HVAC, district heating/cooling, food and beverage, pharmaceuticals, and clean chemical processes.

Strengths: Easy maintenance, reconfigurable plate packs, quick gasket replacement.

The gasket design permits easy inspection and cleaning, making it a preferred solution for applications requiring hygienic standards or flexible operation.

Welded Plate Heat Exchangers

To handle higher pressures and aggressive media, welded plate heat exchangers use laser or TIG-welded seams instead of gaskets. There are several subtypes:

- Bloc-Type Welded Exchangers

These feature plates welded into a block with internal flow passages and external frames. They withstand higher pressure and temperature compared to gasketed types, and are often deployed in gas processing, refinery, and chemical industries.

Advantages: Gasket-free operation, compactness, high integrity under stress.

Cleaning: Some models have openable covers or channels for chemical cleaning.

- Wide-Gap Plate Exchangers

Designed to handle fibrous or particulate-laden fluids, these exchangers have greater spacing between plates and specially shaped flow channels. They are well suited for pulp, wastewater, or slurry-like fluids that would clog standard plates.

Use Cases: Sugar refining, paper mills, industrial effluent treatment.

Key Feature: Flow geometry prevents blockage and enables higher throughput.

Printed Circuit Heat Exchangers (PCHE)

Among the most advanced types, printed circuit heat exchangers are manufactured by chemically etching flow channels into metal plates and then diffusion bonding them together. These can operate at very high pressure (up to 600 bar) and very high temperatures (up to 800 °C).

Applications: Hydrogen production, LNG, supercritical CO₂ cycles, and compact nuclear reactors.

Advantages: Exceptional strength, very high area density, and compact design.

PCHEs represent the cutting edge of compact heat exchanger technology, bringing plate-style thermal efficiency to extreme-duty applications.

Summary: why plate heat exchanger is more efficient?

Plate heat exchangers stand out as one of the most efficient and versatile thermal solutions across multiple industries. Their superior heat transfer performance, compact design, and low operating costs position them as the optimal choice wherever efficiency and space savings matter.

From district energy and HVAC to oil refining and advanced hydrogen processes, PHEs continue to displace bulkier and less efficient alternatives. With innovations like wide-gap plates, welded blocks, and printed circuit designs, the range of applications for plate exchangers continues to grow.

If you need further consultation and discussion, please feel free to contact us.

Email: info@shphe.com

WhatsApp / Cell: +86 15201818405