“Moving Forward Green” | SHPHE Receives Product Carbon Footprint Certification

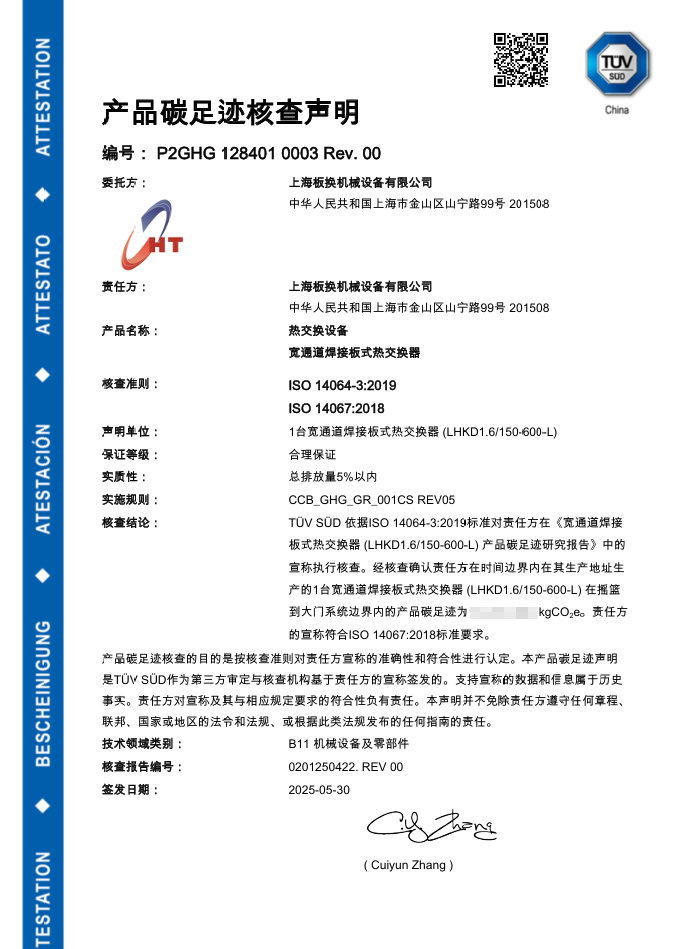

Recently, SH‑PHE’s heat exchange equipment successfully completed a product lifecycle carbon footprint assessment, earning certification from an independent, authoritative third-party organization. Building upon our 2024 organizational greenhouse gas verification statement, this marks another significant milestone in our transition toward greener, low-carbon operations and establishes a solid foundation for deepening green manufacturing and management practices.

What is “Product Carbon Footprint”?

Product carbon footprint refers to the systematic accounting of greenhouse gas emissions generated during all stages of a product’s lifecycle—from raw material extraction and manufacturing to logistics, sales, usage, service, and end-of-life disposal. This comprehensive measurement across the entire supply chain is a key environmental impact indicator and reflects a company’s commitment to sustainable development.

Why This Matters

Market Access & Competitiveness

Achieving product carbon footprint certification serves as a “green passport” for exporting products, helping SH‑PHE boost international market competitiveness.Reliable Emissions Data for Clients

We can now provide clients with accurate and verifiable carbon emissions data, empowering them and downstream industries to strengthen carbon management and pursue sustainability goals.

Flagship Product: Wide‑Channel Welded Plate Heat Exchanger

Among SH‑PHE’s product line, the wide-channel welded plate heat exchanger stands out. With over 20 years of refinement and a wealth of global installations, it’s widely used in industries such as alumina, fuel-grade ethanol, wastewater treatment, sugar, starch, papermaking, and fermentation. It excels at heating or cooling high-solid, fibrous, viscous, or high‑temperature fluids, offering excellent anti-clogging and erosion resistance.

Ongoing Innovation & Optimization

In recent years, SH‑PHE has aggressively promoted new product development, integrating advanced international design concepts—from flow-guiding optimizations in component parts to bionic-inspired core structures that achieve low resistance and high efficiency. Multiple patent applications have been filed, driving product upgrades.

We’ve also accelerated our digital transformation by deploying advanced production equipment and optimizing processes. These efforts have reduced raw materials and energy consumption, enhanced human–machine collaboration, and improved overall operational efficiency.

Through full-process energy consumption risk analysis and smart energy-monitoring devices on key equipment, we’ve refined energy management and unearthed significant potential for energy savings.

Recognition & Future Plans

We have earned multiple registered certifications for product energy efficiency.

We’ve been recognized as a 4-Star Green Manufacturing Demonstration Factory among the second batch of 2024’s Shanghai green manufacturing models.

Product carbon footprint certification is just the beginning. SH‑PHE will continue to uphold its innovation-first philosophy and, starting with core products, implement a phased and comprehensive product carbon footprint management system. By steadily increasing each product’s “green content,” we aim to inject fresh impetus into our high-quality development and proactively drive industry-wide green advancement in a concrete and impactful way.