News

Find by news

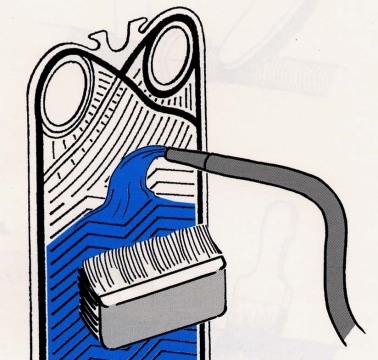

Step-by-Step Cleaning Process for Plate Heat Exchangers

Plate heat exchangers (PHEs) are vital components in various industrial processes, facilitating efficient heat transfer between fluids. Over time, these systems can accumulate fouling—such as mineral scaling, biological growth, and particulate matter—that impairs performance. Regular cleaning is essential to maintain optimal functionality and extend the lifespan of the equipment.

Apr-14-2025

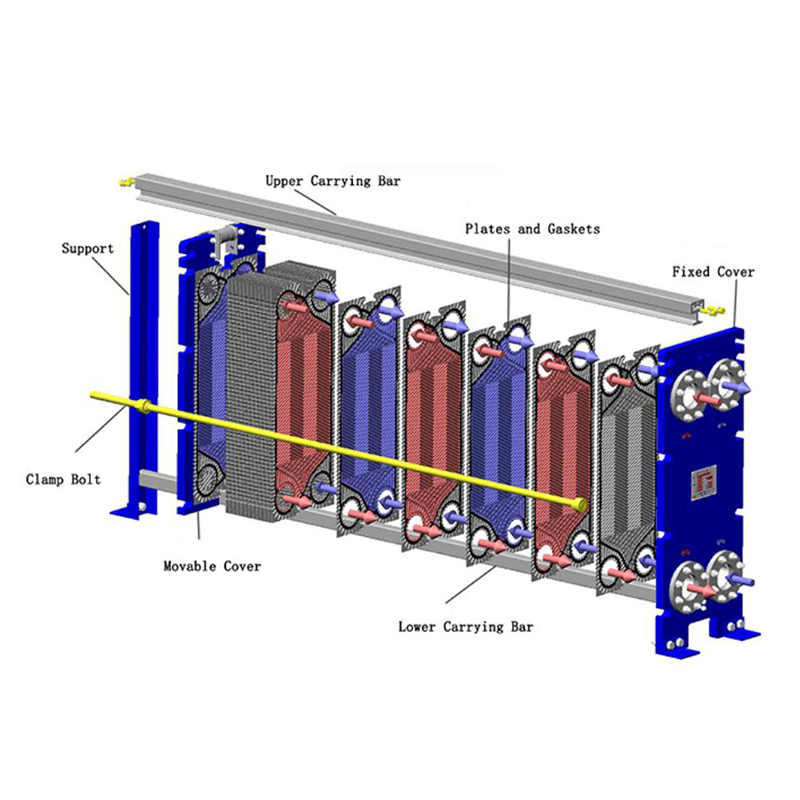

How To Choose/Select a Plate Heat Exchanger

Plate Heat Exchangers (PHEs) are pivotal components in thermal management systems, facilitating efficient heat transfer between two fluids without direct contact. Comprising a series of thin, corrugated metal plates, these exchangers create alternating channels for hot and cold fluids, maximizing the surface area for heat exchange. This design not only enhances thermal efficiency but also allows for a compact footprint, making PHEs ideal for applications where space is at a premium.

Apr-14-2025

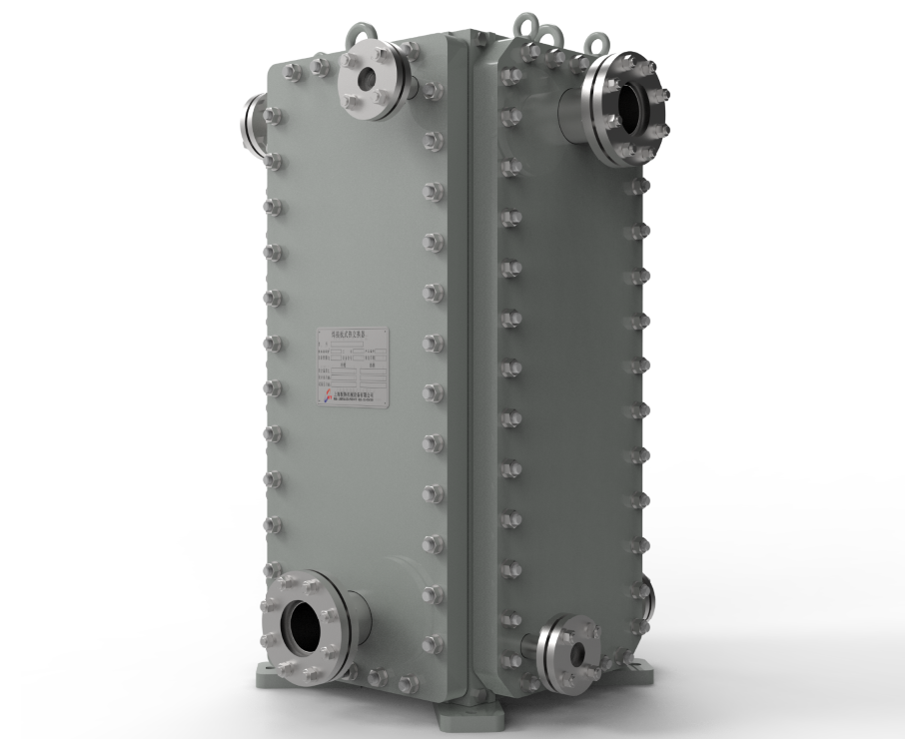

The Superiority of Plate Heat Exchangers in Modern Applications

A plate heat exchanger (PHE) is a device engineered to transfer thermal energy between two fluids without allowing them to mix. It comprises a series of thin, corrugated metal plates that create separate channels for each fluid. These plates are assembled in a frame, forming parallel flow paths that facilitate efficient heat exchange. The design ensures a large surface area within a compact footprint, making PHEs highly effective in various industrial applications.

Apr-10-2025

What Are The Different Types of Heat Exchanger?

In the intricate tapestry of industrial operations and everyday conveniences, heat exchangers emerge as pivotal components, orchestrating the seamless transfer of thermal energy between mediums. These devices are indispensable, ensuring processes operate within desired thermal parameters, thereby optimizing efficiency and safety.

Apr-10-2025

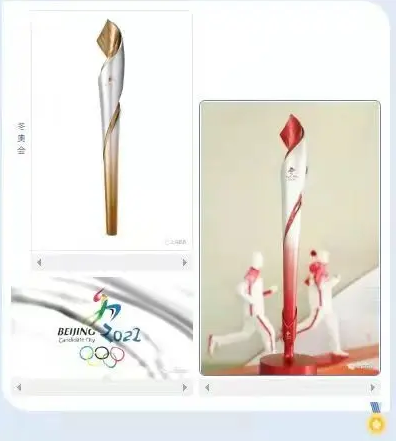

The products of SHPHE contribute to the Beijing Winter Olympics

The day of Beijing Winter Olympics is getting close! Feiyang, which is a torch in Winter Olympics and Paralympics, not only have a very dynamic andenergetic appearance, but also its shell contains black technology. That’s why Feiyang’s shell can resist fire and high temperature, and at same time it also can use in extremely cold weather. Sinopec Shanghai Petrochemical Corporation provide Feiyang’s shell with carbon fiber ,which is processed from petroleum products into many tows, and every tow contains 12,000 carbon fiber. After three-dimensional system, finally become the shell of the torch. No seams or no pores are visible, the shape of the whole torch looks like one integrated mass.

Jan-24-2022

SHPHE received repeat order from customer in Australia

Recently, SHPHE received repeat order from customer in Australia, Which is the second order for the customer to order Wide gap welded plate heat exchanger from our company in recent years.

Aug-19-2021

SHPHE attended 38th ICSOBA

During November 16 to 18, 2020, the 38th International Conference and Exhibition of the International Committee for Study of Bauxite, Alumina & Aluminium

Dec-05-2020

SHPHE has complete quality assurance system from design, manufacturing, inspection and delivery. It is certified with ISO9001, ISO14001, OHSAS18001 and hold ASME U Certificate.